For small manufacturing companies, managing operations efficiently is often the difference between growth and struggle. Manual systems or disconnected software can create bottlenecks, errors, and delays. An ERP system for small manufacturing companies brings all critical functions—production planning, inventory control, finance, supply chain, and quality—into one unified platform. This article explores the best ERP systems for small manufacturers, what features to look for, and real-world examples of businesses that have thrived after implementation.

Key Factors to Consider When Choosing an ERP System

Selecting the right ERP system is a long-term investment, and small manufacturers need to weigh several factors carefully.

Scalability: As your company grows, your ERP should grow with you. Choose a system that supports new users, larger transaction volumes, and additional modules without requiring a complete overhaul.

Total Cost of Ownership: Consider more than the upfront license or subscription cost. Factor in implementation, training, support, and upgrades. Look for transparent pricing and flexible plans designed for small businesses.

Integration Capabilities: Your ERP should connect seamlessly with accounting software, CRM platforms, and e-commerce tools. Strong integration ensures all data flows smoothly across departments.

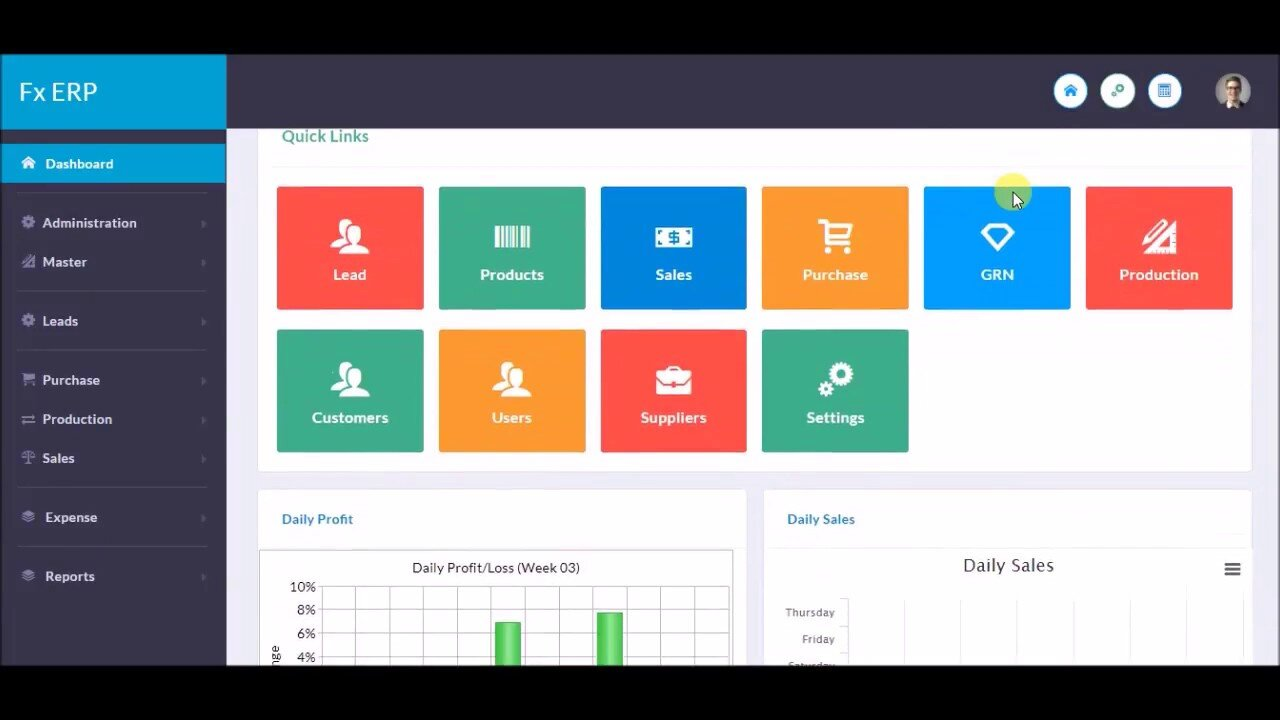

Ease of Use: A user-friendly interface is critical. Complex systems discourage adoption, while intuitive dashboards and navigation reduce training time.

Vendor Reputation: Choose vendors with proven success in small manufacturing. Check case studies, reviews, and references before committing.

Must-Have Features for Small Manufacturing ERP

The best ERP systems for small manufacturers come with features that directly address daily challenges:

Inventory Management: Real-time tracking of raw materials, WIP, and finished goods helps prevent shortages, overstocking, and costly delays.

Production Planning and Scheduling: Accurate planning ensures efficient resource use, reduced bottlenecks, and on-time deliveries. Features like work order management and capacity scheduling are vital.

Shop Floor Control: Barcode scanning, machine data collection, and real-time production updates give supervisors visibility to act quickly.

Quality Management: Built-in tools for inspections, non-conformance tracking, and compliance reporting reduce errors and ensure product consistency.

Financial and Cost Accounting: Integrated financials allow manufacturers to track job costs, analyze variances, and monitor margins alongside operations.

Analytics and Reporting: Dashboards that highlight KPIs such as lead time, yield, and resource utilization help managers make smarter decisions.

Benefits of Implementing ERP in Small Manufacturing

Small manufacturers that adopt ERP systems experience tangible improvements across operations.

Streamlined Operations: Centralizing data reduces duplication and manual processes, leading to higher productivity.

Better Inventory Control: With automated tracking, companies maintain optimal stock levels, minimize carrying costs, and ensure raw material availability.

Improved Decision-Making: Real-time analytics empower managers to forecast demand, adjust schedules, and allocate resources efficiently.

Cost Reduction: Automation reduces human error, optimizes resource usage, and highlights inefficiencies, leading to higher profitability.

Compliance and Security: ERP systems help meet industry standards and regulatory requirements while keeping sensitive data secure.

Steps for Successful ERP Implementation

Implementing an ERP system requires careful planning.

- Define Objectives: Clarify what you want to achieve, such as reducing lead times or improving cost control.

- Select the Right ERP: Evaluate systems designed for small manufacturing, considering cost, scalability, and usability.

- Involve Stakeholders: Include managers, IT staff, and shop floor employees in planning and decision-making.

- Provide Training and Support: Equip employees with training to ensure smooth adoption.

- Test Before Launch: Conduct pilot runs to identify bugs or workflow issues.

- Monitor and Optimize: Track performance metrics post-implementation and adapt as needed.

Case Studies of Small Manufacturers Using ERP

XYZ Company (Metal Fabrication): After adopting an ERP, they reduced lead times, improved deliveries, and increased customer satisfaction.

ABC Manufacturing (Plastic Components): Automation through ERP helped cut costs, improve inventory accuracy, and expand production capacity.

PQR Industries (Electronics): By automating purchasing and scheduling, they reduced errors, improved collaboration, and boosted profitability.

LMN Technologies (Machinery Production): ERP improved supply chain visibility, scheduling, and supplier communication, leading to faster production cycles.

DEF Innovations (Consumer Products): ERP integration across design, production, and distribution improved product quality, reduced time-to-market, and increased sales.

Conclusion

The best ERP system for a small manufacturing company should combine affordability, scalability, and essential features such as production planning, inventory management, and real-time analytics. By implementing the right ERP software, small manufacturers can streamline operations, cut costs, enhance decision-making, and ensure compliance with industry standards. The right ERP is not just a tool but a strategic partner that empowers small businesses to grow, adapt, and stay competitive in a fast-paced market.